Description

The SBT500 is a uniquely designed brake tester for the testing of brakes on trackless mining machines (TMM) as per either SANS 1589:2012 and/or ISO 3450:2011

The SBT500 is designed as a stand-alone unit that is permanently installed at a mine at or close to the workshop where the machines are serviced. The brake tester can test all the brake systems i.e. service, neutral and park/emergency brakes with a full traceable report which is time and date stamp with a picture of every test. The brakes/systems are also tested with a 10% overload to enable trending of the brake degradation. The ideal is that the brakes are tested after every service thereby excluding gray areas around testing after intervention.

With the SBT500 every wheel set is tested individually and then combined in the software to calculate the correct brake performance

Basic Machine Specifications

Machine weight: 5000 kg x 2 units

Activation: Two hydraulic cylinders

Testing speed: 390 mm/min

Maximum pulling force: 500t

Application

Testing of the different braking systems on TMM i.e.

Analysis of data to provide mine with dashboard report on

Service brake plus 10% overload

Neutral brake (if applicable) plus 10% overload

Park/emergency brake plus 10% overload

Overall vehicle brake condition

Trending data on brake performance

Integration into ERP system

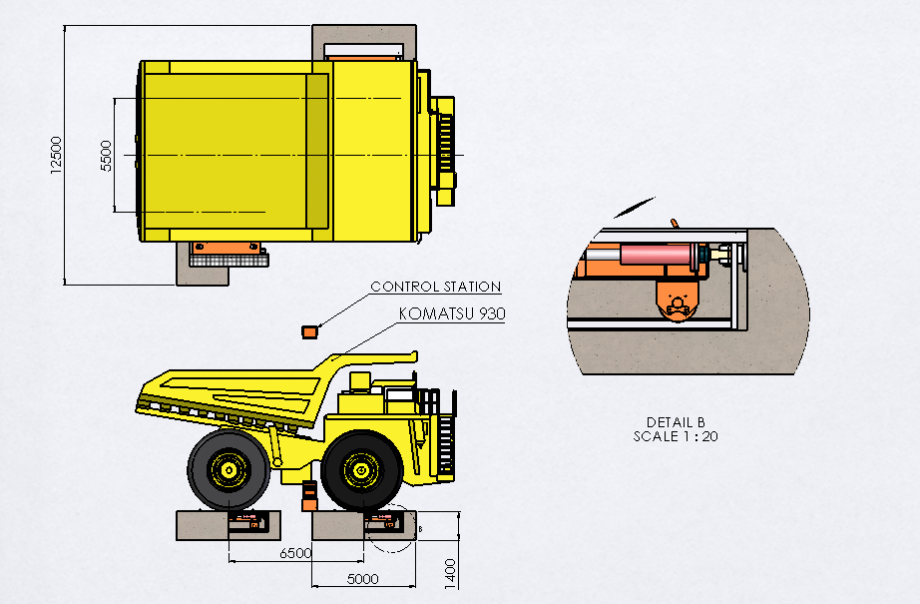

Basic Machine Dimensions

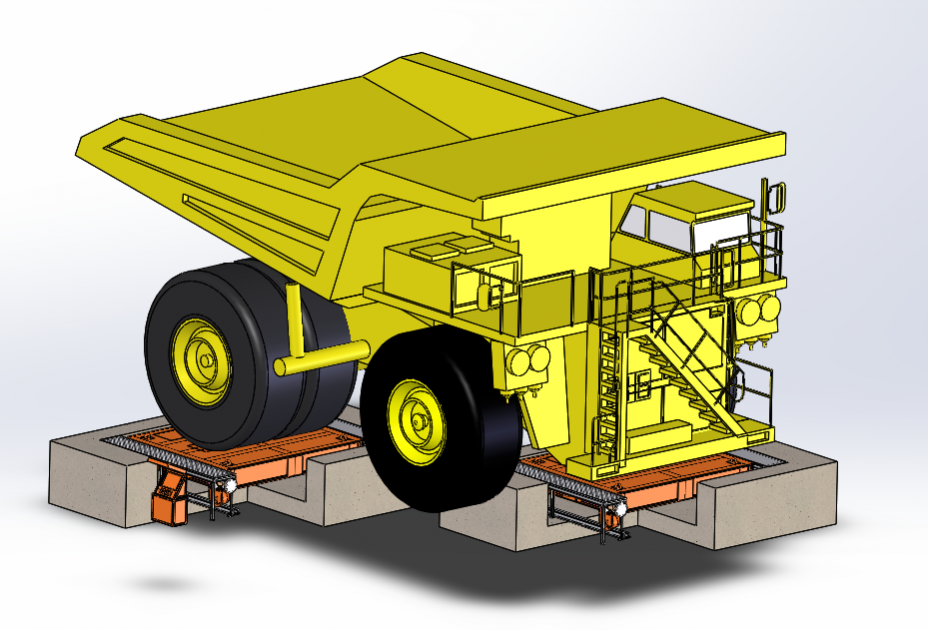

The basic site installation and the basic machine dimensions as installed on concrete slab is as shown (Design of slab is supplied by CMTI):